Uses of Pharmaceutical Purified Water and Applicable Industries

Pharmaceutical purified water is essential in various applications to ensure product safety and quality. Here are some of its primary uses:

Uses:

- Formulation of Medicines:

- Used as a solvent for drugs and other pharmaceutical products.

- Equipment Cleaning:

- Ensures sterile and contaminant-free surfaces for manufacturing equipment.

- Reconstitution of Powders:

- Dilutes or dissolves active pharmaceutical ingredients.

- Laboratory Applications:

- Used in analytical tests and experiments.

- Sterile Products:

- Essential in the production of injections, eye drops, and other sterile preparations.

- Biotechnology:

- Vital for processes involving cell cultures and other biological applications.

Applicable Industries:

- Pharmaceutical Industry:

- Integral for drug manufacturing and quality control.

- Biotechnology:

- Used in research, development, and production of biotechnological products.

- Hospitals and Healthcare:

- Critical for preparing medications and cleaning medical equipment.

- Cosmetic Industry:

- Ensures purity and safety in the production of skincare and personal care products.

- Laboratories:

- Used in various research and analytical procedures.

Pharmaceutical purified water is a cornerstone in maintaining high standards of safety and efficacy across multiple industries.

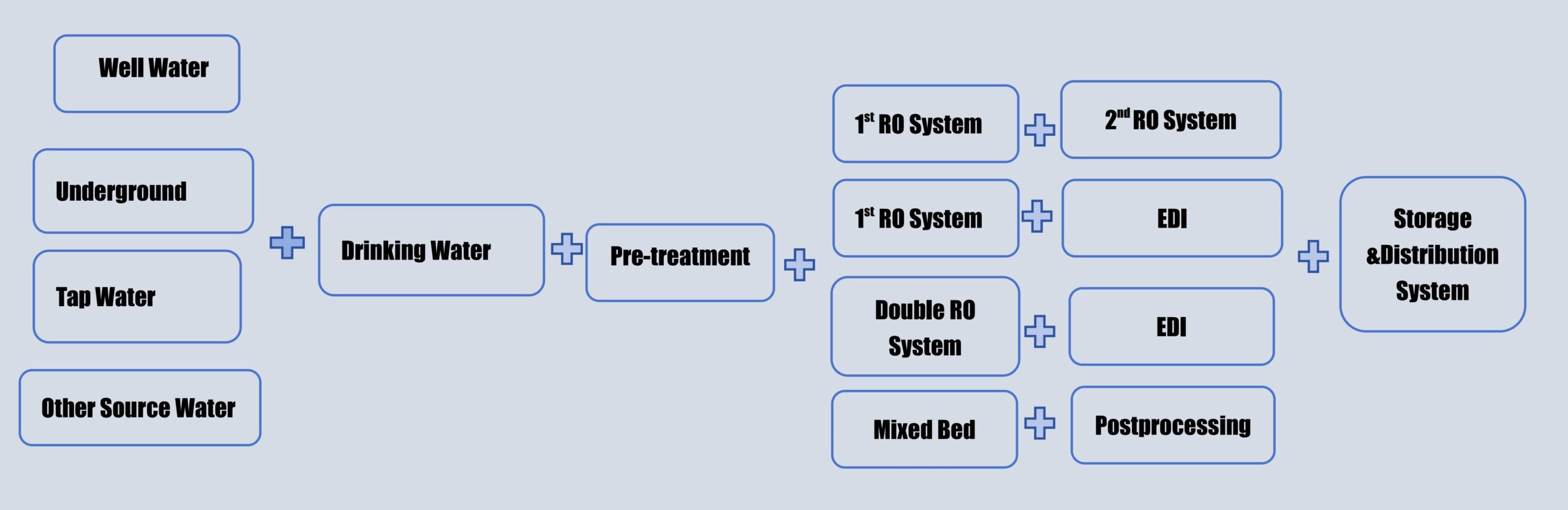

The composition of a complete set of purified water equipment

Pre-treatment Device

Our pre-treatment devices are crucial for preparing raw water for further purification. These systems remove large particles, sediments, and chlorine, protecting downstream equipment and ensuring the longevity and efficiency of the entire water treatment system. With our advanced pre-treatment solutions, you can achieve consistent and reliable water quality for all your pharmaceutical applications.

Reverse Osmosis System

Our Reverse Osmosis (RO) systems are engineered to provide high-purity water, crucial for pharmaceutical applications. Below are the detailed technical parameters, the quality of water achieved, and the brands of the parts used in our systems.

Technical Parameters

- Capacity Range: 0.25 to 50 m³/h

- Operating Pressure: ≤ 1.6 MPa

- Recovery Rate: 50-75%

- Salt Rejection Rate: ≥ 99%

- Feed Water Conductivity: < 2000 μS/cm

- Output Water Conductivity: < 5 μS/cm

- Operating Temperature: 5-45°C

- Material:

- Frame and Piping: Stainless Steel/Carbon Steel

- Membrane Housing: FRP/Stainless Steel

- Control Panel: PLC with HMI interface

- Automation: Full Automatic/Semi-Automatic

Water Quality Achieved

- Conductivity: < 5 μS/cm

- Total Organic Carbon (TOC): < 50 ppb

- Bacteria: < 10 CFU/100 mL

- Endotoxins: < 0.25 EU/mL

- pH Range: 5-7.5

Brands of Parts

- Membranes: Dow Filmtec, Hydranautics

- Pumps: Grundfos, CNP

- Valves: Alfa Laval, Burkert

- Pressure Vessels: Pentair

- Instrumentation: Siemens, Yokogawa

- Control Systems: Siemens, Schneider Electric

- Filters: Pall, GE

- UV Sterilizers: Wedeco, Hanovia

Our RO systems are built with components from these leading brands to ensure durability, efficiency, and compliance with stringent pharmaceutical water quality standards. By integrating these high-quality parts, we provide reliable and effective water treatment solutions tailored to meet the unique demands of the pharmaceutical industry.

EDI System

Electrodeionization (EDI) systems are advanced water treatment solutions that produce high-purity water by combining ion exchange, membrane separation, and electrochemical regeneration. Our EDI systems are designed to consistently deliver ultrapure water, crucial for pharmaceutical and other high-purity applications.

Technical Parameters

- Capacity Range: 0.5 to 30 m³/h

- Operating Pressure: 0.1 – 0.5 MPa

- Recovery Rate: ≥ 90%

- Feed Water Conductivity: < 20 μS/cm

- Output Water Conductivity: < 0.1 μS/cm

- Operating Temperature: 5-40°C

- Material:

- Frame and Piping: Stainless Steel

- EDI Modules: FRP/Stainless Steel

- Control Panel: PLC with HMI interface

- Automation: Full Automatic/Semi-Automatic

Water Quality Achieved

- Conductivity: < 0.1 μS/cm

- Total Organic Carbon (TOC): < 20 ppb

- Bacteria: < 1 CFU/100 mL

- Endotoxins: < 0.03 EU/mL

- pH Range: 5-7

Brands of Parts

- EDI Modules: Ionpure, Dow EDI

- Pumps: Grundfos, CNP

- Valves: Alfa Laval, Burkert

- Pressure Vessels: Pentair

- Instrumentation: Siemens, Yokogawa

- Control Systems: Siemens, Schneider Electric

- Filters: Pall, GE

Our EDI systems utilize components from these trusted brands to ensure high efficiency, durability, and consistent production of ultrapure water. These systems are ideal for meeting the rigorous water quality standards required in the pharmaceutical industry and other sectors demanding high-purity water.

Storage and Distribution System

Our Storage and Distribution Systems are designed to maintain the integrity and quality of purified water throughout the entire process, ensuring consistent and reliable supply for pharmaceutical applications.

Key Features

- Material: Stainless Steel (304/316L)

- Capacity Range: 500L to 50,000L

- Insulation: Polyurethane foam for temperature control

- Surface Finish: Mirror-polished/Matte finish

- Cleaning System: Integrated CIP/SIP system

Technical Parameters

- Operating Temperature: 5-85°C

- Pressure Rating: 0.1 – 0.3 MPa

- Flow Rate: Customizable based on application needs

- Control System: PLC with HMI for automated operation and monitoring

- Piping: Sanitary design with seamless stainless steel tubes

- Valves: Automated and manual valves for precise control

Water Quality Maintained

- Microbial Control: UV sterilization and ozone disinfection options

- Particle Control: 0.2-micron absolute filters

- Conductivity: Maintains < 5 μS/cm

Brands of Parts

- Pumps: Grundfos, CNP

- Valves: Alfa Laval, Burkert

- Filters: Pall, GE

- UV Sterilizers: Wedeco, Hanovia

- Instrumentation: Siemens, Yokogawa

- Control Systems: Siemens, Schneider Electric

Our storage and distribution systems ensure that high-purity water remains uncontaminated and readily available for your pharmaceutical processes. With robust design and high-quality components, we provide reliable solutions tailored to your specific needs.

Steam Boiler

Our steam boiler is specifically engineered to meet the rigorous demands of the pharmaceutical industry, ensuring reliable and consistent steam production for critical processes like pasteurization in pharmaceutical water treatment equipment. Built with precision and designed for efficiency, our steam boiler is an essential component in maintaining the highest standards of purity and safety in pharmaceutical operations.

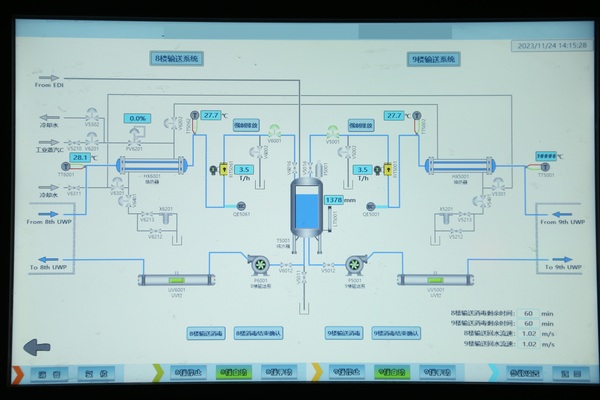

Electric Control System

Our Electric Control Cabinet is a state-of-the-art solution designed to optimize and secure your water treatment operations. It integrates a total electric control system that automates every step of the process, ensuring consistent and efficient performance.

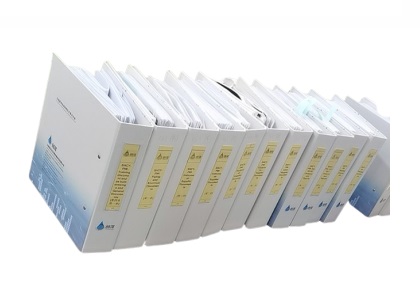

Verification Documents

Validation documentation is critical in the pharmaceutical water treatment industry as it ensures that all processes and equipment consistently meet regulatory standards and quality requirements. This documentation provides verifiable proof that the system is operating correctly, ensuring the safety, efficacy, and compliance of pharmaceutical products.

Type and Technical Parameter

Type | Capacity(M3/H) | Pipe DN (mm) | WP (MPa) | Material | Work Method |

| CY-RO-0.25 | 0.25 | DN20 | ≤1.0 | Stainless Steel/Carbon Steel | Full Auto/Semi Automatical |

| CY-RO-0.5 | 0.5 | DN20 | ≤1.0 | Stainless Steel/Carbon Steel | Full Auto/Semi Automatical |

| CY-RO-1 | 1 | DN25 | ≤1.0 | Stainless Steel/Carbon Steel | Full Auto/Semi Automatical |

| CY-RO-2 | 2 | DN32 | ≤1.0 | Stainless Steel/Carbon Steel | Full Auto/Semi Automatical |

| CY-RO-3 | 3 | DN40 | ≤1.0 | Stainless Steel/Carbon Steel | Full Auto/Semi Automatical |

| CY-RO-5 | 5 | DN50 | ≤1.0 | Stainless Steel/Carbon Steel | Full Auto/Semi Automatical |

| CY-RO-10 | 10 | DN75 | ≤1.0 | Stainless Steel/Carbon Steel | Full Auto/Semi Automatical |

| CY-RO-20 | 20 | DN100 | ≤1.6 | Stainless Steel/Carbon Steel | Full Auto/Semi Automatical |

| CY-RO-30 | 30 | DN125 | ≤1.6 | Stainless Steel/Carbon Steel | Full Auto/Semi Automatical |

| CY-RO-40 | 40 | DN150 | ≤1.6 | Stainless Steel/Carbon Steel | Full Auto/Semi Automatical |

| CY-RO-50 | 50 | DN200 | ≤1.6 | Stainless Steel/Carbon Steel | Full Auto/Semi Automatical |