Welding Requirements for Pharmaceutical Water Treatment Equipment

Introduction Welding plays a critical role in the construction of pharmaceutical water treatment equipment. Proper welding techniques are essential to ensure the integrity, cleanliness, and durability of the system. Adhering to stringent welding requirements helps prevent contamination, ensures compliance with industry standards, and maintains the high purity of the water produced. This article outlines the […]

Installation Guidelines for Pharmaceutical Water Treatment Equipment

Introduction Proper installation of pharmaceutical water treatment equipment is essential to ensure system performance, regulatory compliance, and long-term reliability. A well-executed installation minimizes downtime, prevents contamination, and sets the foundation for successful operation. This article provides a comprehensive guide to the key steps and considerations for installing pharmaceutical water treatment equipment. 1. Pre-Installation Planning 1.1. […]

Source Water Quality Impact on Produced Water Quality

Introduction The quality of source water plays a crucial role in determining the effectiveness and efficiency of pharmaceutical water purification systems. Different source water characteristics can significantly impact the quality of the produced water, potentially affecting the final product’s compliance with regulatory standards. This article explores how various aspects of source water quality influence the […]

Qualification Documents for Pharmaceutical Purified Water Equipment

Introduction In the pharmaceutical industry, the qualification and validation of purified water equipment are essential to ensure compliance with regulatory standards and maintain water quality. Key documents such as Installation Qualification (IQ), Operational Qualification (OQ), and Design Qualification (DQ) are crucial in this process. This article outlines the purpose and content of these qualification verification […]

Design Requirements for Pharmaceutical Purified Water Equipment

Introduction The design of pharmaceutical purified water equipment is crucial for ensuring the consistent production of high-purity water that meets industry regulations. Proper design helps maintain water quality, reduces contamination risks, and supports efficient operation. This article explores the key design requirements for pharmaceutical purified water systems. 1. Compliance with Regulatory Standards 1.1. cGMP and […]

Material Requirements for Pharmaceutical Purified Water Equipment

Introduction The material selection for pharmaceutical purified water equipment is critical to ensuring the production of high-quality water that meets stringent industry standards. The right materials contribute to system durability, prevent contamination, and maintain water purity throughout the purification process. This article outlines the key material requirements and considerations when selecting equipment for pharmaceutical purified […]

Considerations for Purchasing a Pharmaceutical Water Purification System

1. Compliance with Industry Standards 2. Water Quality Requirements 3. System Capacity and Scalability 4. Reliability and Maintenance 5. Operational Costs 6. Customization and Flexibility 7. Supplier Reputation and Support 8. Installation and Validation 9. Conclusion When purchasing a pharmaceutical water purification system, it’s essential to consider factors like regulatory compliance, water quality, system capacity, […]

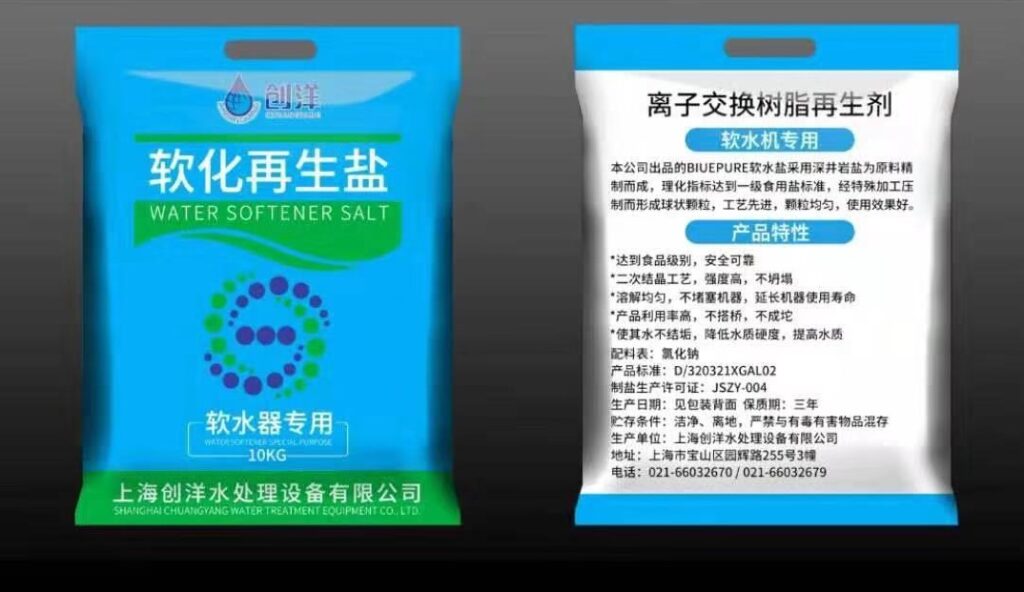

Guide to Replacing Consumables in Pharmaceutical Purification Systems

Introduction Maintaining a pharmaceutical water purification system is crucial for ensuring consistent water quality that meets industry standards. Regular replacement of consumables is a key aspect of system maintenance, preventing contamination and ensuring operational efficiency. This guide will outline the essential consumables that need to be replaced, the recommended replacement frequency, and tips for optimizing […]